vsi crusher Конструкционные

vsi crusher Конструкционные

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER - OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact Sandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption. The autogenous "rock on rock" crushing technique results in several Stationary VSI impact crushers, Sandvik VSI Crusher The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision. Astec VSI crushers are available Vertical Shaft Impactors - Astec

VSI Crushers - REMco

VSI Crushers Quality Vertical Shaft Impactors REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits. Feed rates are from 15 to 1500 TPH. Machine drive powers range from REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits. Feed rates are from 15 to 1500 TPH. Machine drive powers range from 50hp to 1500hp and feed sizes can be from 4” (100 VSI Crushers - REMcoV-Slam™ VSI Models from Stedman are vertical shaft impactors for all your coarse-to-fine crushing needs. VSI crushers offer significant savings over higher-priced competitive crushers. The V-Slam, with its low horsepower Vertical Shaft Impactors - VSI Crushers - Stedman

What Is A Vertical Shaft Impactor (VSI) Primer?

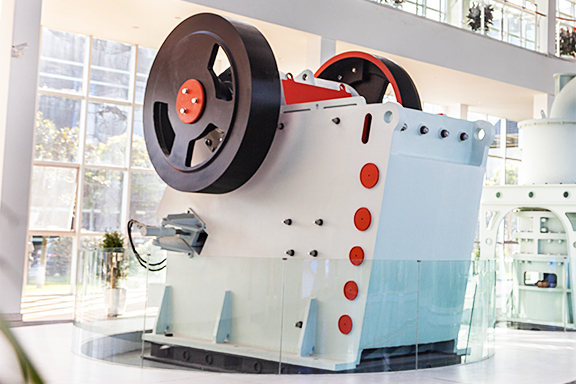

The VSI is typically used after a primary or secondary crusher. This makes a VSI ideal for making sand and for making coarse and medium aggregates for concrete/asphalt production. Feed size and characteristics will affect SANDVIK CV200 RANGE (VSI) 7 STANDARD SCOPE OF CRUSHER FEED HOPPER fitted with Bi-flow adjustment system ROTOR with all necessary standard wear parts fitted. One complete spare rotor with standard wear parts and tip plates. Non standard wear parts are available for abrasive material.SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different composition ...Crusher - Wikipedia

Modeling of Vertical Shaft Impact Crushers

Energy in the VSI Crusher, proceedings of European Symposium on Comminution and Classification 2015, Gothenburg, September 2015. Paper B. Simon Grunditz, Magnus Evertsson, Erik Hulthén, Magnus Bengtsson, The Effect of Rotor Tip Speed of a Vertical Shaft Impactor on the Collision Energy Spectrum, proceedings of Minerals Engineering2021年11月22日 KESIMPULAN. Mesin impact crusher merupakan mesin yang membentuk material menjadi bentuk kubus dengan paling seragam sebagai produk jadi karena kemampuan konsistennya yang memecahkan agregat secara seragam melalui benturan. Benturan dapat dilakukan dengan hammer yang bergerak cepat seperti pada Mengenal Mesin Impact Crusher Secara Mendalam – CV BAKTIVSI APPLICATIONS Rock and mineral deposits vary widely from site to site, country to country, and around the world. Crushing plants, circuit variations, and product requirements are infinite. For this reason, any crusher, if it is to suceed, perform reliably and economically, it must be designed to fit the specific needs of your job.VSI Crushers - AGGRETEK Vertical Shaft Impactors

Crushers - VSI Crusher Ore Sizer

The Ore Sizer OM 120 is our largest machine designed for the high production quarries and mining operations. This single or twin drive unit can produce up to 700 tons per hour of product. With a choice if the seven or eight port rotors, and power consumption as low as 0.7 kW per ton this unit can provide solutions to the mining and quarrying ...produced by the Sandvik VSI crusher, packing densities of their sand has increased from 0.625 previous Hawaiian sand to 0.727 Sandvik manufactured sand. The fineness modulus (FM) was de- creased from an original figure of 3.36 to 2.76 with the manufactu- red sand produced in the Sandvik VSI crusher. These figures show the high quality of ...MEETING YOUR EVER- CHANGING REQUIREMENTS THE VSI CV228 VSI impact crusher. Sandvik CV228 VSI impact crusher is manufactured for tertiary and quaternary applications. It can handle anything from hard and abrasive rocks to soft, moist and even sticky materials. It's an efficient, versatile piece of equipment, designed to perform well with the most difficult materials. Email us Request a quote.CV228 VSI crusher — SRP

Portable Vertical Impact (VSI) Crushers With Screen

WHY MEKA PORTABLE VERTICAL IMPACT (VSI) CRUSHERS WITH SCREEN? • Produces cubical-shaped end products at a consistent quality using rock-to-rock crushing action. • Rotor design enable consistent material flow and high throughput. • Highly efficient on board screen for product classification. • Minimized wear part costs.Twister VSI crushers use two variations of VSI crushing. The first is vertical shaft impact crushing where rock is fed onto a table type rotor which accelerates and then discharges the rock at high speed against steel Vertical Shaft Impactor - VSI Crushers - Impact CrushersA conventional quarry process may consist of at least three crushing stages, a minimum installation beginning with a primary (jaw) crusher to reduce all the material to less than 150-200mm. A secondary (cone) crusher is used to crush this down to around 40mm, and finally a tertiary (VSI) crusher can shape and grade the final product ready for use in CRUSHER DEPARTMENT : KOTOBUKI ENGINEERING

Canica VSI VERTICAL SHAFT IMPACT CRUSHERS

• Multiple internal crusher configuration options • Pinion gear drive option for models 2050 through 2500 • Fully equipped test crushing facility • Reliable parts and service from experienced dealer organization • 3 year crusher warranty Vertical Shaft Impactor Benefits The ® Canica VSI Advantage • Very cubicle productNo other VSI crusher offers such a high output level at such a low cost. “Everything that was promised was true: increased production, reduced maintenance downtime, no increase in power consumption and better quality aggregate.” Sand and gravel producer, Serbia. Had a non-Sandvik VSI that was retrofitted with a Sandvik rotor. 50%UP TOCRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS - SRP2006年12月1日 Particle shape characteristics were assessed from flow measurements in a standard cone. The vertical shaft impact crusher (VSI) produces gravel that is a good alternative to natural gravel. The ...(PDF) Measuring characteristics of aggregate material from

Vertical Shaft Impactors Product Overview

Impactors (VSI) crushers on the market. Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material. A properly configured Canica® VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability. At Canica®, we offer one ofOre Sizer designs, manufactures and ships the OM Series VSI crusher through a global network of over twenty dealers. Making the right shaped product in high volume at the lowest cost is the key objective in fine aggregate production. With headquarters based on the North Somerset coast of England, Ore Sizer (UK) Ltd leads the way with the lowest ...Home - VSI Crusher Ore Sizer2017年9月1日 Researchers from the JKMRC, on the other hand, proposed a methodology for a more direct application of the Whiten crusher model to the VSI (Napier-Munn et al., 1996, Kojovic et al., 1998), which is briefly described as follows: 1. Set the parameters of the classification function (Eq. (1)) as: K 1 = 0 (all particles have a chance of being ...Mathematical modeling of a vertical shaft impact crusher using

- Шаровая мельница китайский

- chongqing huashi оборудование для дробления и измельчения материалов

- дробилка валковая 1000 тч

- вертикальный фрезерный станок самый быстрый

- камнедробильный шлифовальный станок

- экспортер щековой дробилки в китае php оборудование

- дробильная машина установка

- мельницы для энергии ветра

- камнедробилка Орегон на продажу

- поисковый механизм пескоструйное оборудование

- камень рок дробилка orompg

- какая фабрика производит x щековые дробилки

- использовали каменные дробилки для малого масштаба добычи золота

- Кенийская Щековая Дробилка

- содержание колеи железной руды

- каменная дробилка в райгарх c g

- дробилка используемая в тунисе

- добыча железа процесса

- вертикали помола цемента процесс мельница

- железная руда дробилка